rockwell hardness test aluminum|hardest grade of aluminum : distributor Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as . Resultado da 15 de fev. de 2024 · - ESSAS INFORMAÇÕES ESTÃO NOS COMENTÁRIOS TAMBÉM ⏬SITE DO CLOUDDY .

{plog:ftitle_list}

WEBGobble is a mini-game of the Fancade app, you are a horrible giant monster able to devour everything, everything but people, you are allergic to people. Who created Gobble? This .

Furthermore, the hardness of aluminum alloys can also be measured with specific hardness testers, such as Vickers hardness testers, and the Rockwell hardness testing method. This indicates that the hardness .The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented .

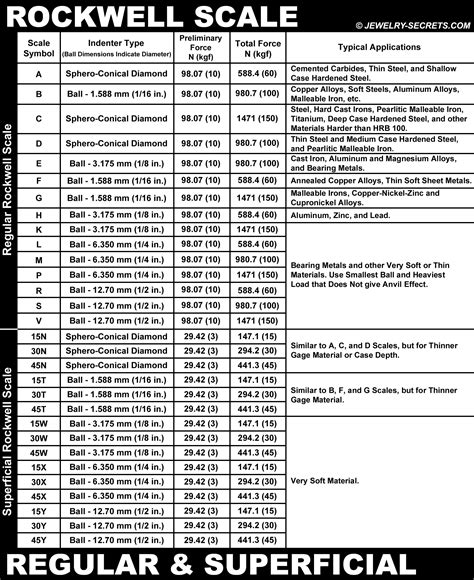

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges . The Rockwell scale is a hardness scale based on indentation .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .

Rockwell hardness does have a relationship to tensile strength in some structural alloys, such as steel and aluminum. The Rockwell hardness test involves making an indentation on the test material. The indenter is either .Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. Brinell hardness of Aluminium is approximately 240 MPa.

Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your .

PDF | On Apr 1, 2020, Armin Yazdanshenas and others published Rockwell Hardness Testing on an Aluminum Specimen using Finite Element Analysis | Find, read and cite all the research you need on .A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.

rockwell hardness scale for aluminum

water vapour permeability test method

Hardness of 6061 Alloy. Brinell hardness of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is approximately 105 MPa. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .

How to use the Rockwell hardness test for quick hardness testing in the lab or production environment. Vickers Hardness testing (HV) . Adding very small amounts of alloying elements to aluminum can increase tensile strength, yield strength and hardness compared to pure aluminum. The most important alloying elements are Si, Mg, Cu, Zn and Mn. .Aluminum 6061-T6; 6061-T651. Subcategory: 6000 Series Aluminum Alloy; Aluminum Alloy; Metal; Nonferrous Metal. Close Analogs: . Converted from Brinell Hardness Value: Hardness, Rockwell B: 60: 60 Converted from Brinell Hardness Value: Hardness, Vickers: 107: 107 Converted from Brinell Hardness Value: Ultimate Tensile Strength: 310 MPa:Brinell hardness of 2024 aluminium alloy depends greatly on the temper of the material, but it is approximately 110 MPa. Brinell hardness of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is approximately 95 MPa. Rockwell hardness test is one of the most common indentation hardness tests, that has been .

The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels.The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.

water vapour permeability testing machine

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method . Sheet metal may be too thin and soft to test on a given Rockwell scale without exceeding the minimum thickness and possibly damaging the test window. In this case, a diamond anvil can be used to consistently affect the result. Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is . Rockwell hardness testing is somewhat comparable to Brinell hardness testing, in that it measures a metal’s resistance to penetration, however, it differs in that the depth of the impression is measured, rather than .Fig 1: Rockwell Hardness Test Machine Schematic [9] RHT uses the Rockwell scale, shown in Table 1, to denote different loads, indenters, typical applications,

These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table To determine the Brinell hardness of a metal material, apply a certain load F with a spherical indenter of diameter D onto its surface and maintain it for a specific duration. . The Rockwell hardness test is divided into various scales, each with a wide range of applications. (5) It is important to note that Rockwell hardness values obtained .

An indenter with a hard metal ball or a cone/diamond pyramid is pressed vertically into the surface of the test specimen resting on a solid support. The test load is applied impact-free with . Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0 . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .

zwickroell.com The result of a Brinell method depends on the tested material, force, ball size and dwell time. .Rockwell hardness test for plastics: In this test, a load of 15 or 30 kg is applied to the surface of the plastic material for a few seconds. . It is commonly used to determine the hardness of metals, including steel, aluminum, and copper. Additionally, Rockwell hardness testing is used in the manufacturing of tools, dies, and other .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics. . For example, “HRC 96” for a metal means the hardness of that metal is 96 when .Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. Brinell hardness of Aluminium is approximately 240 MPa.

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .

Figure 1: Schematic hardness and conductivity loop showing the relationship of hardness and conductivity to the heat-treated condition of an aluminum alloy. Figure 2: Hardness and conductivity relationships for several different heat treatable aluminum alloys. Hardness of a part is measured using a typical Rockwell “B” hardness tester.

rockwell hardness chart for aluminum

well testing pseudo steady state permeability calculation

20 de jun. de 2023 · Learn geography the easy way! Learning geography doesn't have to be boring. Do it the easy way with Seterra! In no time, you could learn to locate every single country in the world on a map. Seterra includes fun quizzes that help familiarize you with countries, capital cities, flags, rivers, lakes, and notable geological features.

rockwell hardness test aluminum|hardest grade of aluminum